Structural Wood-to-Wood Connections

SPAX® PowerLags® are the largest selection of code-recognized structural wood-to-wood screws for framing in the industry. Featuring SPAX patented thread technology, they require no pre-drilling, and drive faster and easier than conventional lags and other structural lag screws.

SPAX® Sets the Bar EVERY DAY!

Once you try SPAX Engineered Fasteners, you won’t settle for anything else.

FOR STRONG WOOD-TO-WOOD CONNECTIONS

German engineered and American made, SPAX® PowerLags are professional grade structural screws and sold in job-friendly package quantities, including bulk pails.

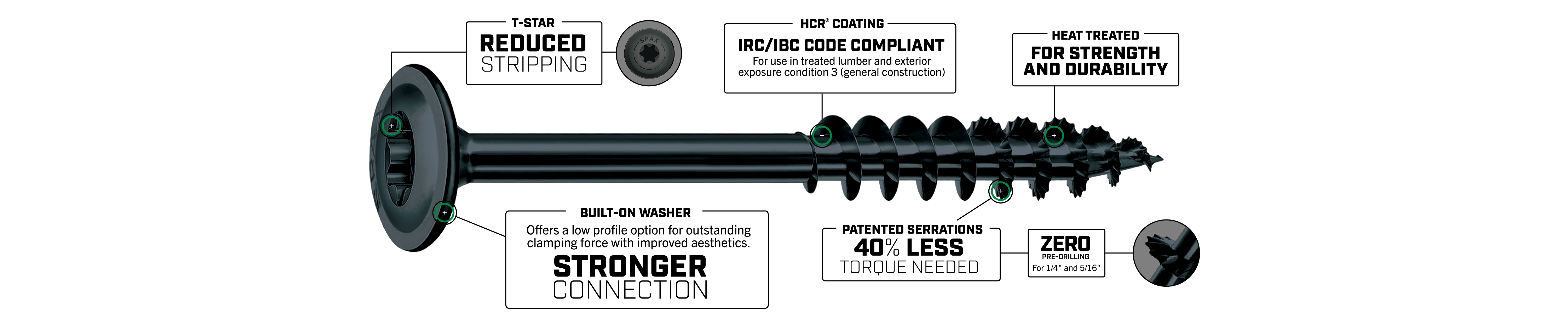

- No pre-drilling required (1/4" and 5/16")

- Heat treated for strength and durability

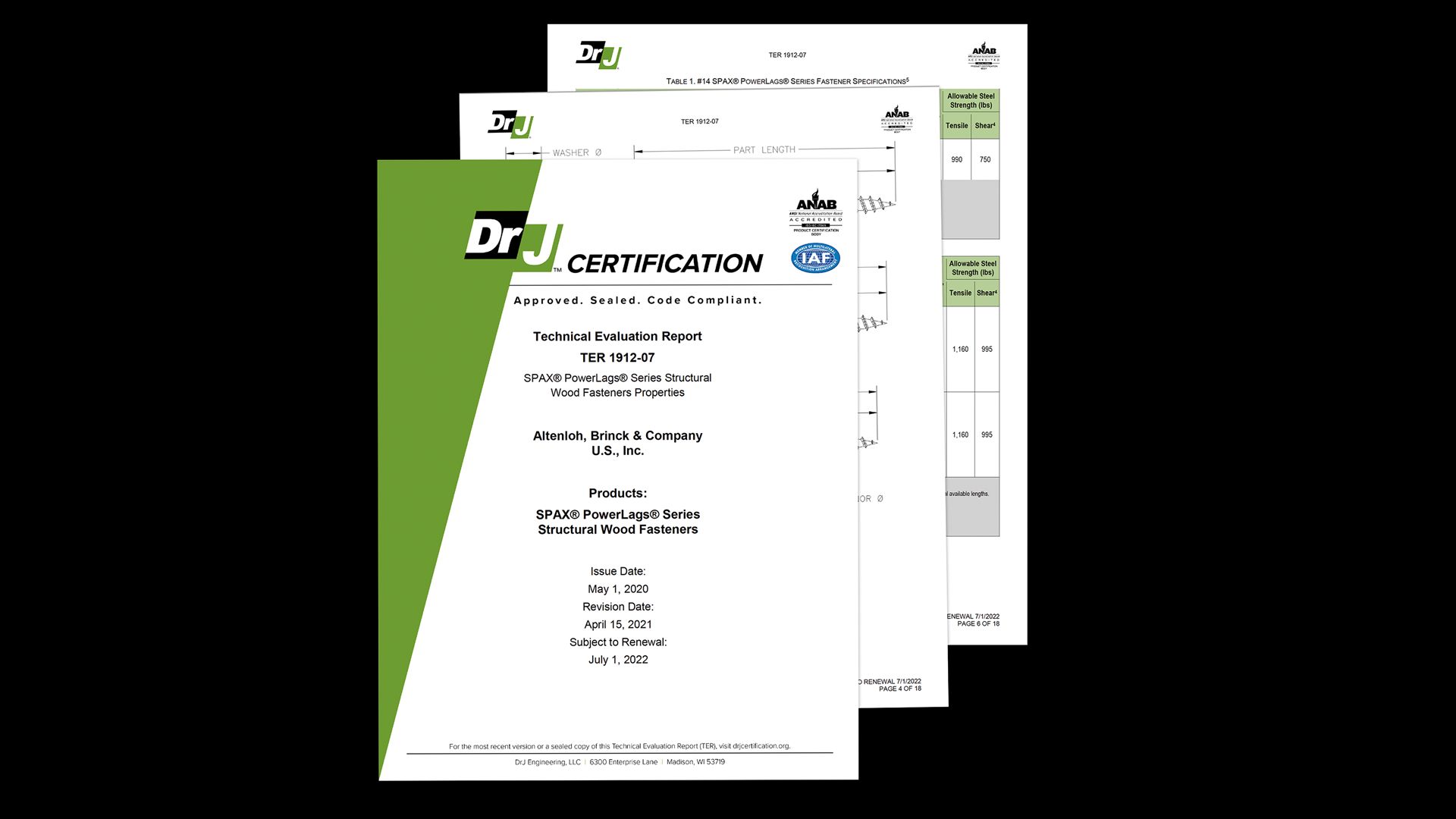

- Independently tested DrJ Engineering Technical Evaluation Reports (TER No. 1912-07; Structural Wood Fastener Properties; TER No. 1711-01; Deck Ledger Attachment and TER No. 1802-03; Multi-ply: Sawn Lumber Assemblies & Engineered Wood Assemblies)

- Patented thread serrations require up to 40% less driving torque to increase installation speed while helping prevent cracking in logs

- Built-on washer head designs eliminate the need and extra cost of a separate washer

- Fastener length stamp on the head provides convenient identification without measuring and aids on-site inspections.

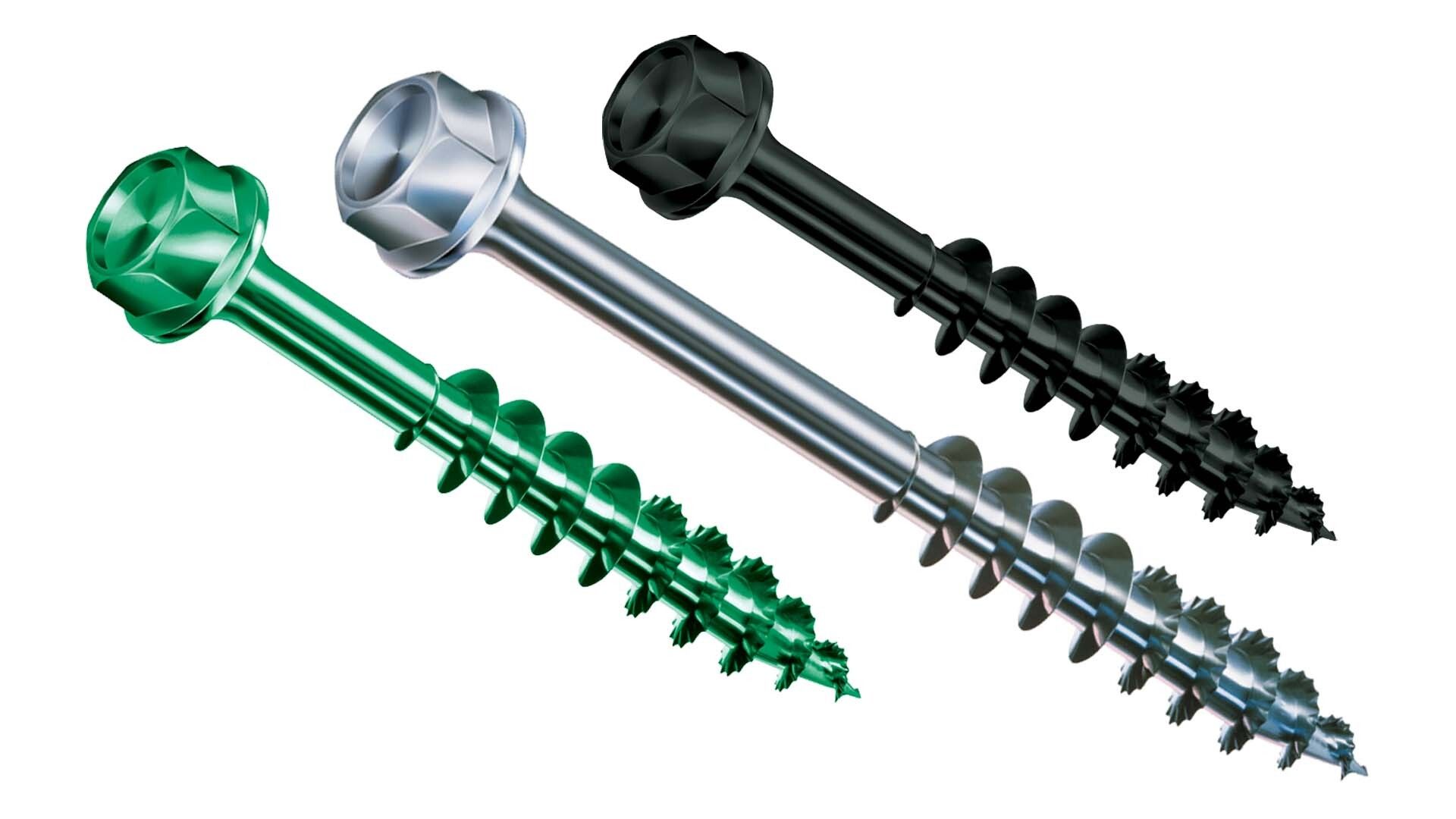

SCREW STYLES

- Hex head style

- T-STAR head style

- Zinc, yellow zinc, coatings options for interior applications

- HCR® (High Corrosion Resistance) coating for exterior use, including treated lumber

Industry's largest selection of code-recognized structural wood-to-wood fasteners

The SPAX FACTOR™ is a simple formula for working smarter. To multiply results and reduce effort – just add SPAX®

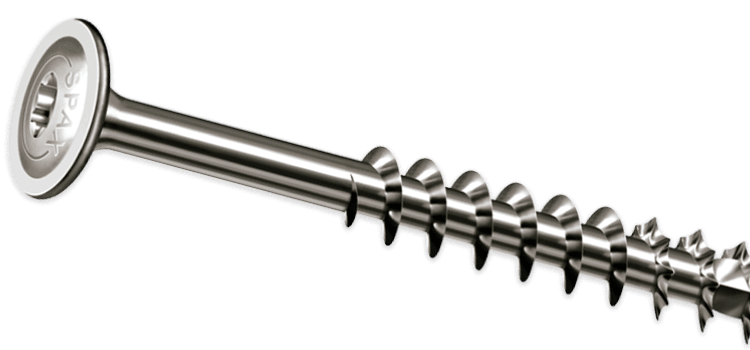

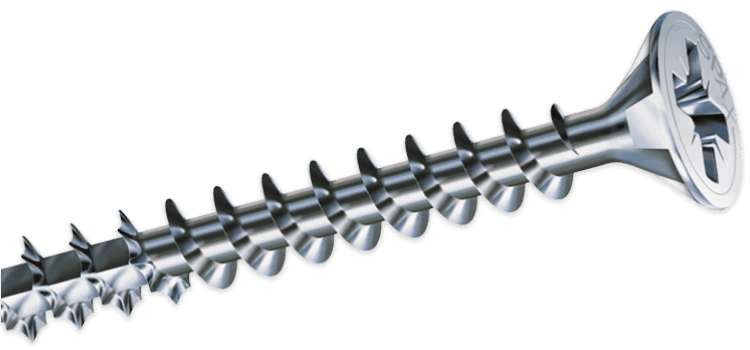

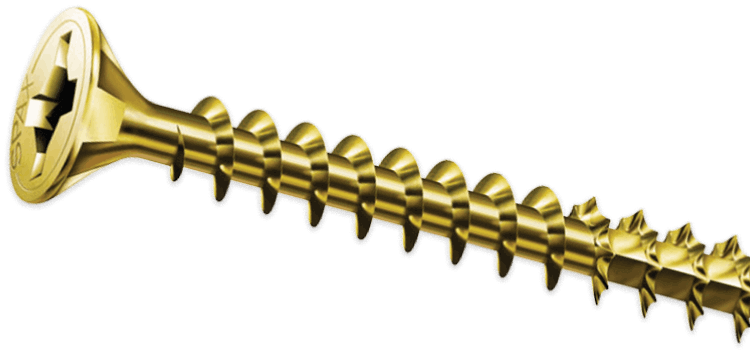

T-STAR WASHER HEAD POWERLAGS®

The low-profile, large diameter head design provides outstanding clamping force and improved aesthetics. Deep T-STAR drive offers excellent bit engagement without requiring a “special” driver bit. Available in 1/4”, 5/16”, and 3/8” diameters, and in lengths up to 10”. SPAX HCR® Coating is approved for use in treated lumber.

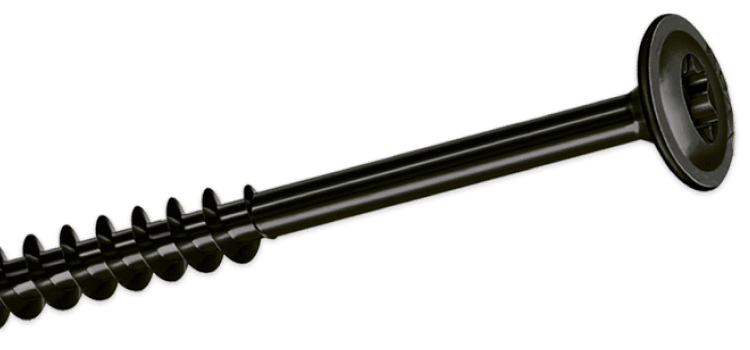

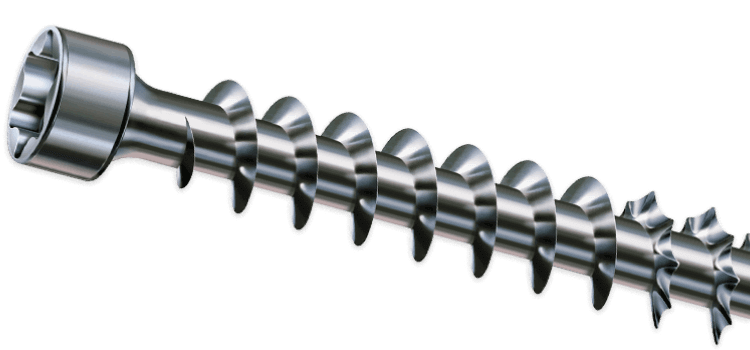

HEX WASHER HEAD POWERLAGS®

Provides maximum driver engagement, especially when using larger diameter/longer length parts in harder wood species. Available in 1/4”, 5/16”, 3/8” and 1/2” diameters, and in lengths up to 12”. SPAX HCR® Coating is approved for use in treated lumber.

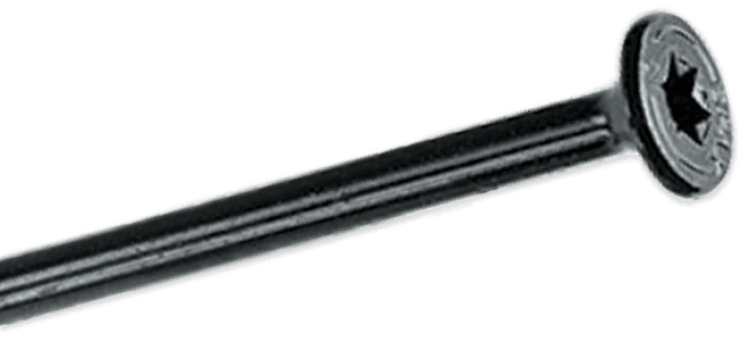

T-STAR PLUS CYLINDRIC HEAD POWERLAGS®

The cylindric head design with full-thread features a low torque / quick installation in critical framing applications. Available in #14 diameter and lengths up to 6-1/4" plus SPAX® exclusive WIROX® coating system, ideal for interior applications.

Related Products

Powerlags® for strong wood-to-wood connections

German engineered and American made, SPAX® PowerLags® are professional grade structural screws, the superior and preferred choice over conventional lag screws/bolts.

No Pre-Drilling

No pre-drilling required (1/4" and 5/16")

Durable

Heat treated for strength and durability

Tested & Certified

Independently tested DrJ Engineering Technical Evaluation Reports.

Increased Installation Speeds

Patented thread serrations require up to 40% less driving torque to increase installation speed while helping prevent cracking in logs.

Built-On Washer Head

Built-on washer head designs eliminate the need and extra cost of a separate washer.

Convenient Identification

Fastener length stamp on the head provides convenient identification without measuring and aids on-site inspections.

NO PRE-DRILLING

Thanks to our proprietary 4CUT™ POINT

SPAX is Independently Tested and Approved

DrJ Engineering TER reports use specialized testing and industry-approved evaluations to certify that products meet specific performance requirements of the appropriate sections of the appropriate building code. We follow ICC AC257 acceptance criteria for all exterior coated screws.

Residential

Building Code

SPAX® Delivers the Highest Structural Values in the Industry

SPAX® POWERLAGS® HIGH PERFORMANCE

SPAX offer the largest selection of code-recognized structural wood-to-wood fasteners in the industry.

Not All Fasteners Are Created Equal

We’re the difference between the parts and complete structure. The connecting point that bonds it all together. From our German engineering and versatile offering, strength and integrity are integrated into each engineered fastener. We provide the power to help you build projects that stay connected stronger for longer.

Do you Know Where Your Fasteners Were Made?

While most of our competitors ship screws in from overseas, we continuously innovate and make our fasteners from the heart of America to reimagine what structural connections should be. That means our products are ready to deliver and stock right now from our Ohio HQ to our neighbors across the U.S.

SPAX

manufactured

in Bryan, OH

90%

of structural

wood-to-wood

fasteners

are manufactured overseas

40% Less Torque Needed

Compared to traditional lags.

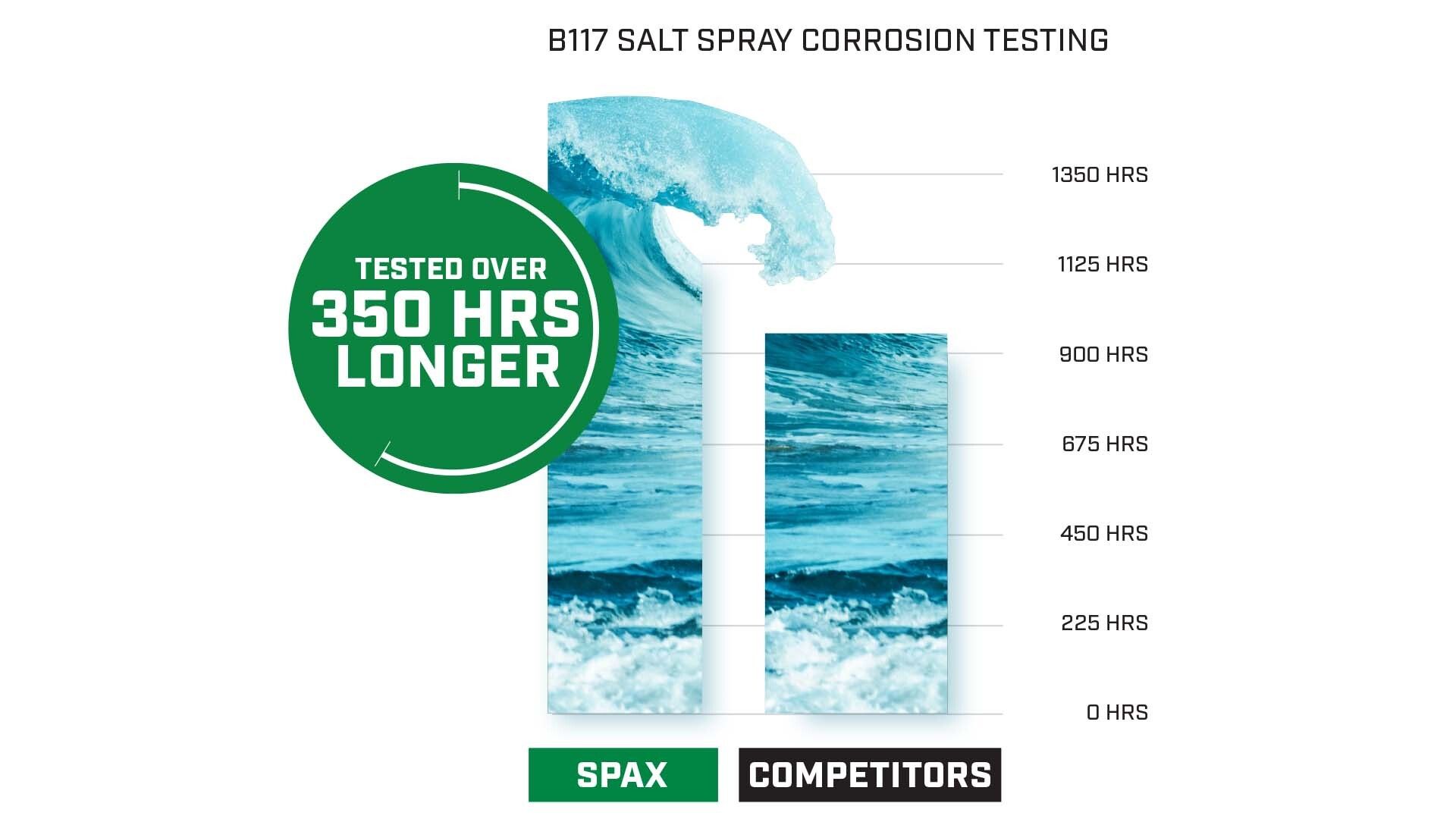

Tested Beyond the Norm

We test and inspect beyond all standards to deliver exceptional structural support—from head to point. Push past what’s expected with time-tested confidence in every connection.

Our Double Barrier Coating

Our HCR® (High Corrosion Resistance) double-barrier coatings offer superior protection with a double barrier. First plated with a zinc base coat and finished with a durable top coat, they’re engineered to hold up to the harshest conditions. Tested and recognized for use in ground contact pressure treated lumber for exterior, freshwater general construction applications (e.g., AWPA UC1-UC4A, UCFA).

DID YOU KNOW?

Some competitors don’t actually test their coatings. They rely on data from their paint company before it makes it onto their screws.

Buy less. Do More.

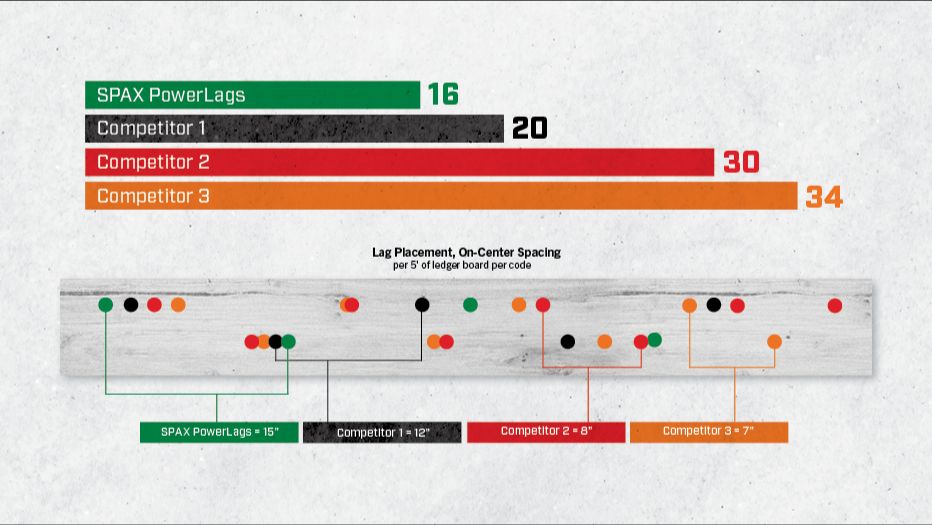

Rely on SPAX to use 200% less fasteners for deck ledgers.

SPAX needs

16

to get the job done

Competitors need up to

40

for the same applcation

Save $ in the aisle. Save $ in labor.

Buy Less, Do More

SPAX® offers contractors the widest deck ledger fastener spacing in the industry — 16 inches on center for a 20-ft. ledger rather than the usual 12. That 70% wider spacing across the deck ledger board means you save on materials, potentially reducing the amount of ledger board fasteners you’ll need by half when compared to other structural screws on the market. Wondering how many ledger screws you need to do the job? Check out our deck ledger fastener calculator online.

With ledger screws that reduce labor and material usage, you can move onto your next job more quickly. Learn more about deck ledger fastener applications for SPAX® PowerLags® in this short video. Or order a sample pack of our industry-leading engineered fasteners.

How Many Fasteners Does it take to do the Same Job?

SPAX® PowerLags® patented serrations provide exceptional gripping power, allowing for a secure connection with fewer screws or bolts compared to our competitors. Save time and effort during installation while ensuring a strong and durable deck attachment with SPAX.

We've Got You Covered

Find the right screw or fastener for your next job with the largest variety of diameters, lengths and head styles in the industry.

Exterior Treated Lumber Approved Fastener Coatings

HCR®

HCR is a dual-barrier coating system designed to extend the longevity of SPAX® fasteners in ground-contact, treated lumber and exterior freshwater applications. Plated with a zinc base coat and finished with a durable top coat, they are engineered to withstand the toughest conditions.

HCR-X™

HCR-X is a SPAX-developed, proprietary, dual- barrier coating system with superior corrosion protection against red rust, designed for use in both treated lumber and freshwater environments.

Stainless Steel

304 stainless steel fasteners provide code- compliant use in ground-contact, pressure-treated, and fire-retardant-treated lumber in general and coastal construction projects. They’re well-suited for use with cedar and redwood decking.

Interior Fastener Coatings

Zinc

“Clear zinc” is tested and recognized for use in untreated and above ground contact pressure treated lumber for interior dry/damp general construction applications.

Yellow Zinc

“Yellow zinc” is tested and recognized for use in untreated and above ground contact pressure treated lumber for interior dry/damp general construction applications.

ECoat

“eCoat” is recognized for use in untreated and above ground contact pressure treated lumber for interior dry/damp general construction applications.

WIROX®

“WIROX” is tested and recognized for use in untreated and above ground contact pressure treated lumber for interior dry/damp general construction applications.